It is an advanced system developed by the internationally leading Validynamic team, designed to perform motor performance tests using a dynamometer load. This system can be used for testing the comprehensive characteristics of motors and drivers, including those for new energy vehicles, servo robots, brushless motors, and other various types of motors and drive systems.

The system is characterized by flexibility in use, precise and stable testing, and safe and convenient operation. It also boasts a wide testing range and powerful analysis functions. This makes it widely applicable in various industries, including motor research and development, testing, quality certification, and selection in fields such as aerospace, aviation, defense, civil applications, universities, research institutions, and robotic servos.

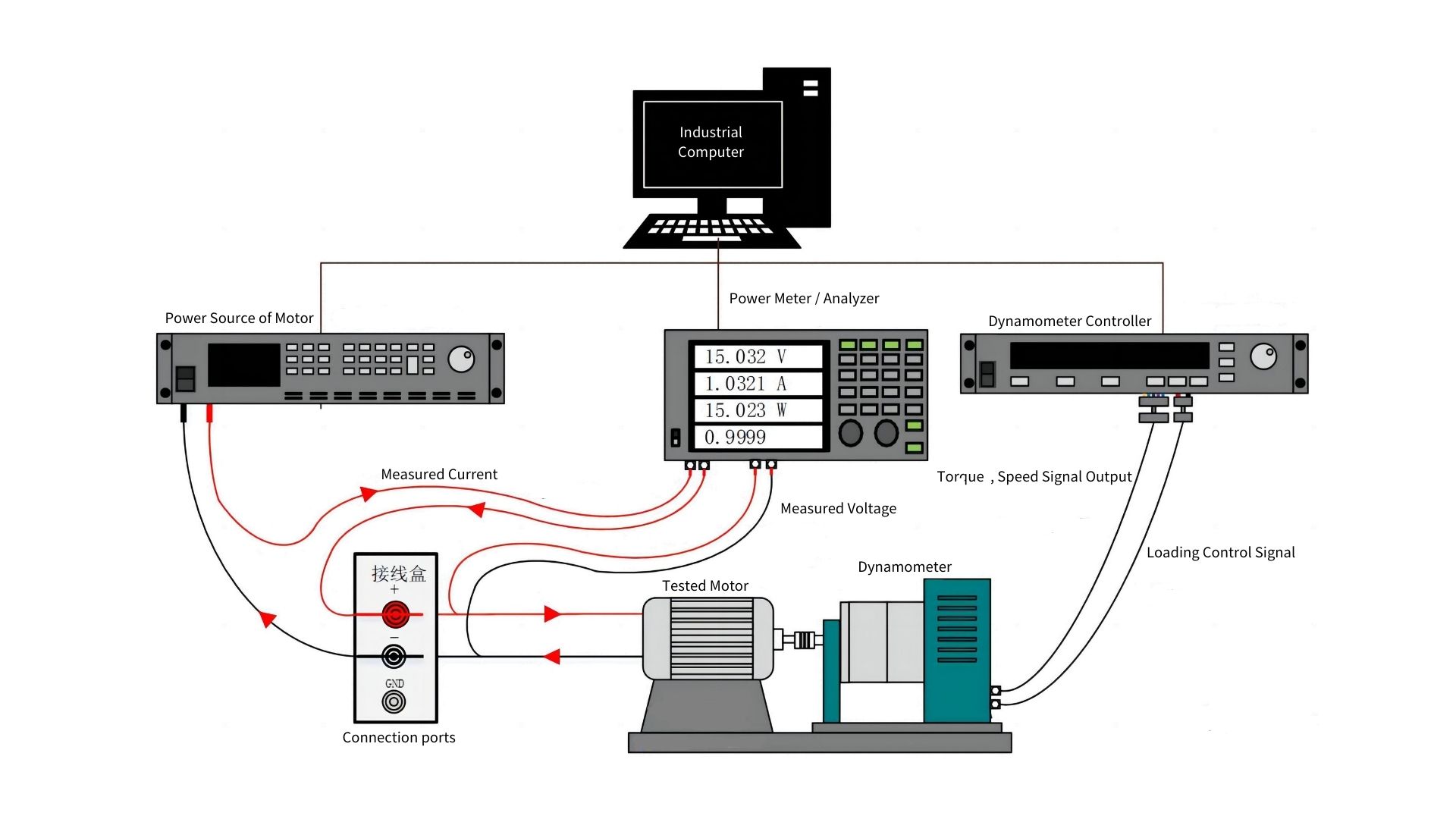

This system is an advanced testing device capable of data acquisition and simulation of various operating conditions under the Windows 7/10 operating system. It consists of components such as the dynamometer, dynamometer controller, power analyzer, and power supply for the tested motor. The dynamometer control system uses the host computer testing software as the core, which communicates with the dynamometer for load control and collects mechanical signals (torque, speed, direction, output power). It also communicates with the power analyzer to read electrical parameters (bus voltage, bus current, input power, UVW voltage, UVW current, etc.). The control computer is responsible for controlling the test system, interlocking, operating, and fault diagnosis. Data is processed via Ethernet, with the control computer’s output sent to a data processing computer for analysis.

Load Performance Testing System Overview:

The load performance testing system for both brushed and brushless motors follows the same basic principle: it uses a dynamometer (or test rig) to apply load and simulate the motor’s performance under various operating conditions.

Components of the System:

Working Principle:

The basic working principle of the system is to load the motor under test using the dynamometer. The test system adjusts the load in accordance with the test parameters (such as torque, speed, and time), while continuously measuring both the electrical and mechanical performance of the motor. The test software ensures that all parameters are recorded, analyzed, and used to generate accurate performance data.

The system can simulate real-world operating conditions and test the motor under different loading scenarios, such as varying speeds and torque, to assess the motor’s performance, efficiency, and other key characteristics like heat generation, stability, and response to dynamic load changes.

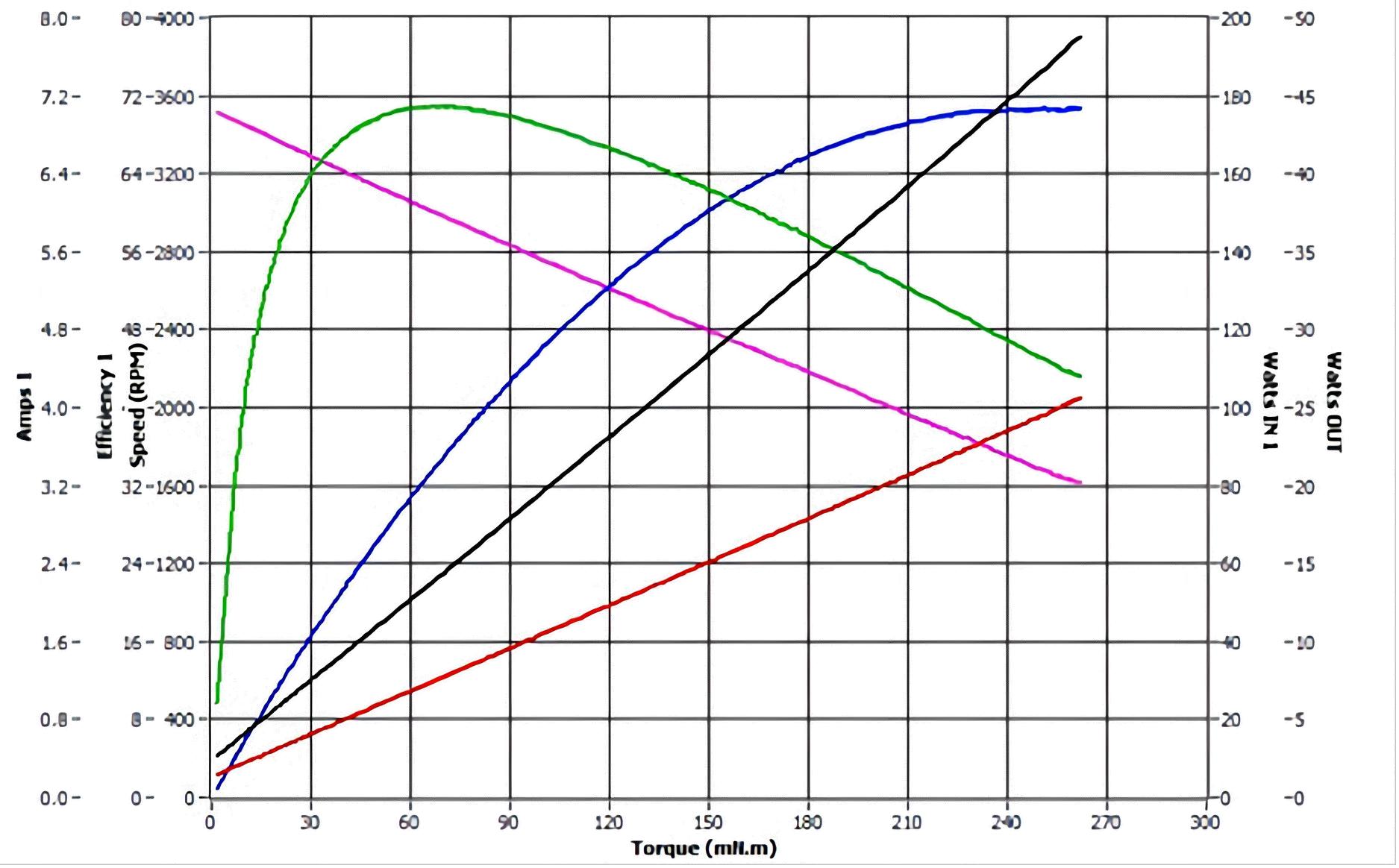

The torque-speed curve is automatically tested and plotted by the industrial control computer software. The measurement of drive motor, drive controller, and system efficiency mainly relies on a high-precision power analyzer and dynamometer. The system automatically measures and provides results in report form.

Test Objective: To draw the torque-speed relationship curve within the motor’s operating range.

Testing Method: The dynamometer is used as the load for the motor under test, and the motor is kept in a heated working state. The DC bus voltage of the motor controller is set to the rated voltage, and the maximum working current is configured. During the experiment, the dynamometer software adjusts the optimal PID values based on the set speed limits and descent speed, automatically applying the load within the set speed range to generate the characteristic curve.

This testing system provides precise and reliable data, making it suitable for comprehensive motor performance analysis across a wide range of industries.

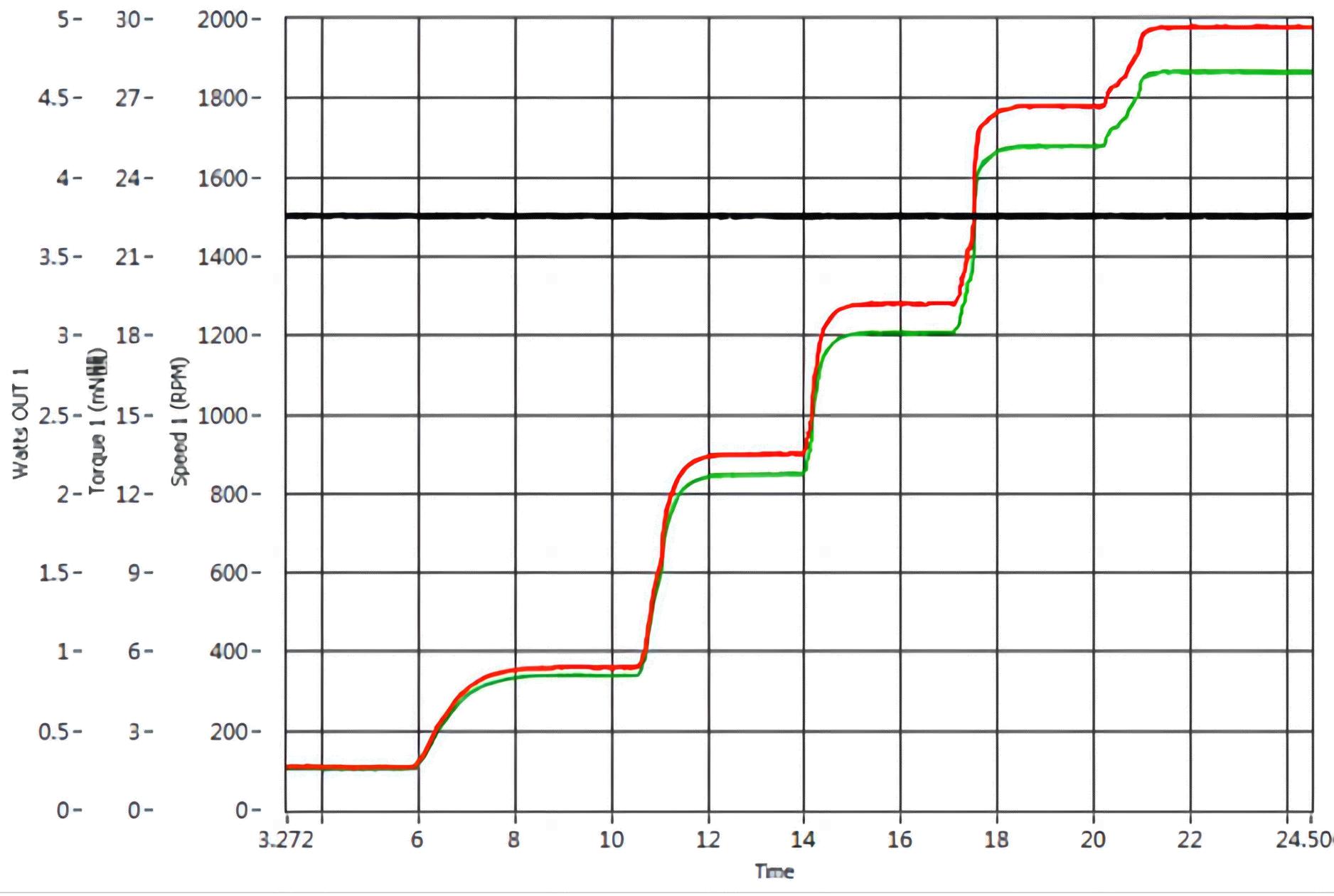

Constant Speed or Constant Torque Testing

Test Objective:

The purpose of the test is to apply a series of specified speed or torque points for loading control, allowing the observation of the motor’s performance under specified operating conditions.

Testing Method:

This type of testing is used to analyze the motor’s performance at specific speed or torque values and is crucial for understanding how the motor behaves under different conditions.

Manual Loading Test

Test Overview:

The manual loading test significantly reduces the PID adjustment time during closed-loop load loading. By using open-loop loading, this test allows for manual control, enabling dynamic loading of any load waveform. This provides users with a true simulation of the motor’s actual operating conditions.

Key Features:

This test is particularly useful when a more specific or varied range of conditions is needed to simulate real-life scenarios or to identify motor performance under customized loading conditions.

Motor Testing with Hysteresis Dynamometer BHD303 + M Test Software.