The Stepper Motor Pull-In and Pull-Out Torque Testing System is a cutting-edge, automated solution designed for precise measurement and analysis of stepper motor performance. Tailored for medium- and small-sized stepper motors, this system streamlines the testing of key torque characteristics, including pull-in torque, pull-out torque, holding torque, and detent torque, while also assessing stepping angles, frequency limits, and more. With one-click operation and real-time data recording, it eliminates the inefficiencies and inaccuracies of manual methods, providing reliable results and comprehensive performance curves with ease.

The testing methods for stepper motor pull-in torque and pull-out torque are clearly defined in the national standard GBT 20638-2006. Four specific methods are described:

Each of these methods has its specific applicability:

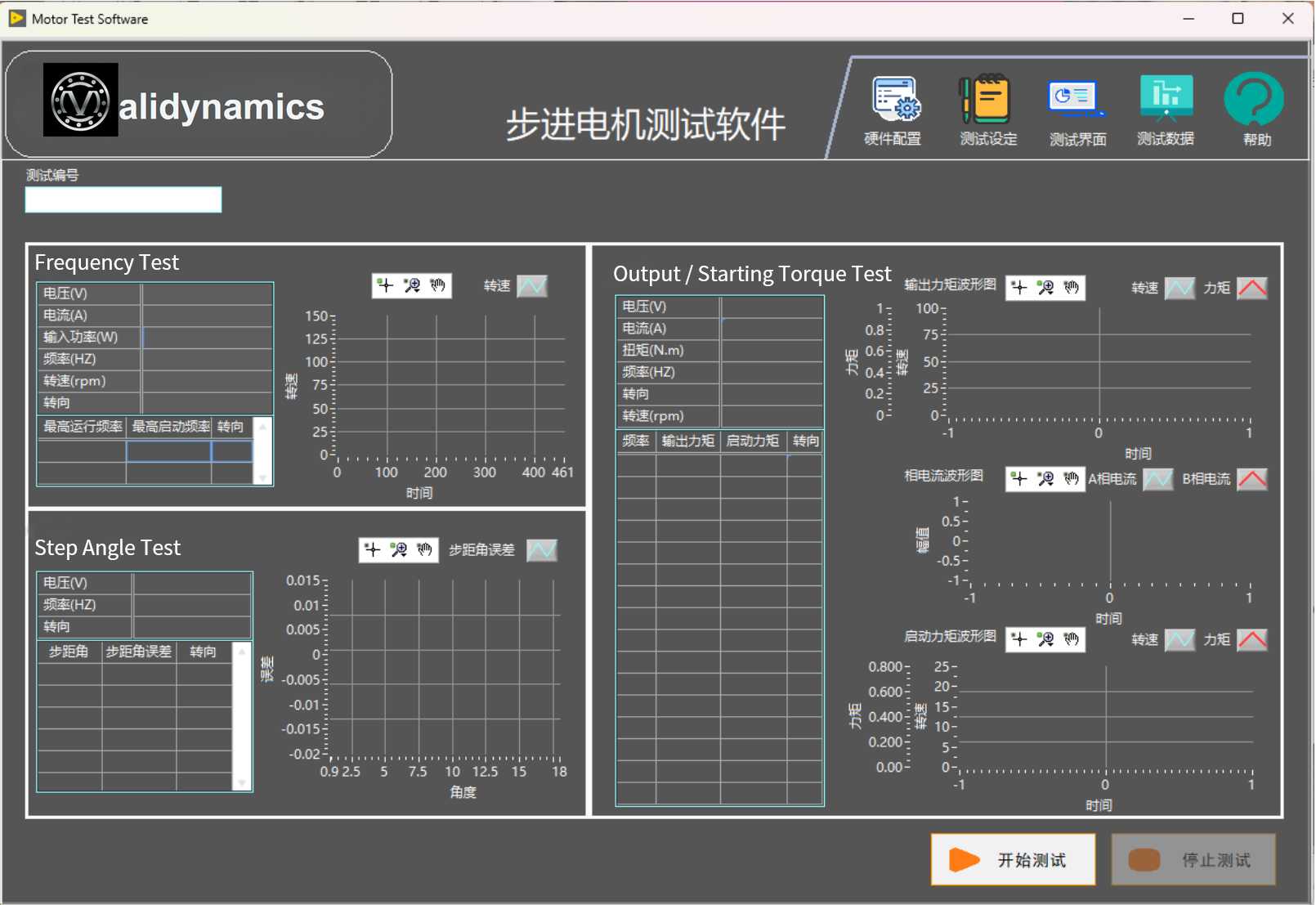

To address these challenges, our company has developed a testing system specifically designed for the pull-in and pull-out torque testing of medium- and small-sized stepper motors. This system enables one-click measurement, automatically outputs results and curves, and resolves the complexity of manual testing and errors caused by human data recording.

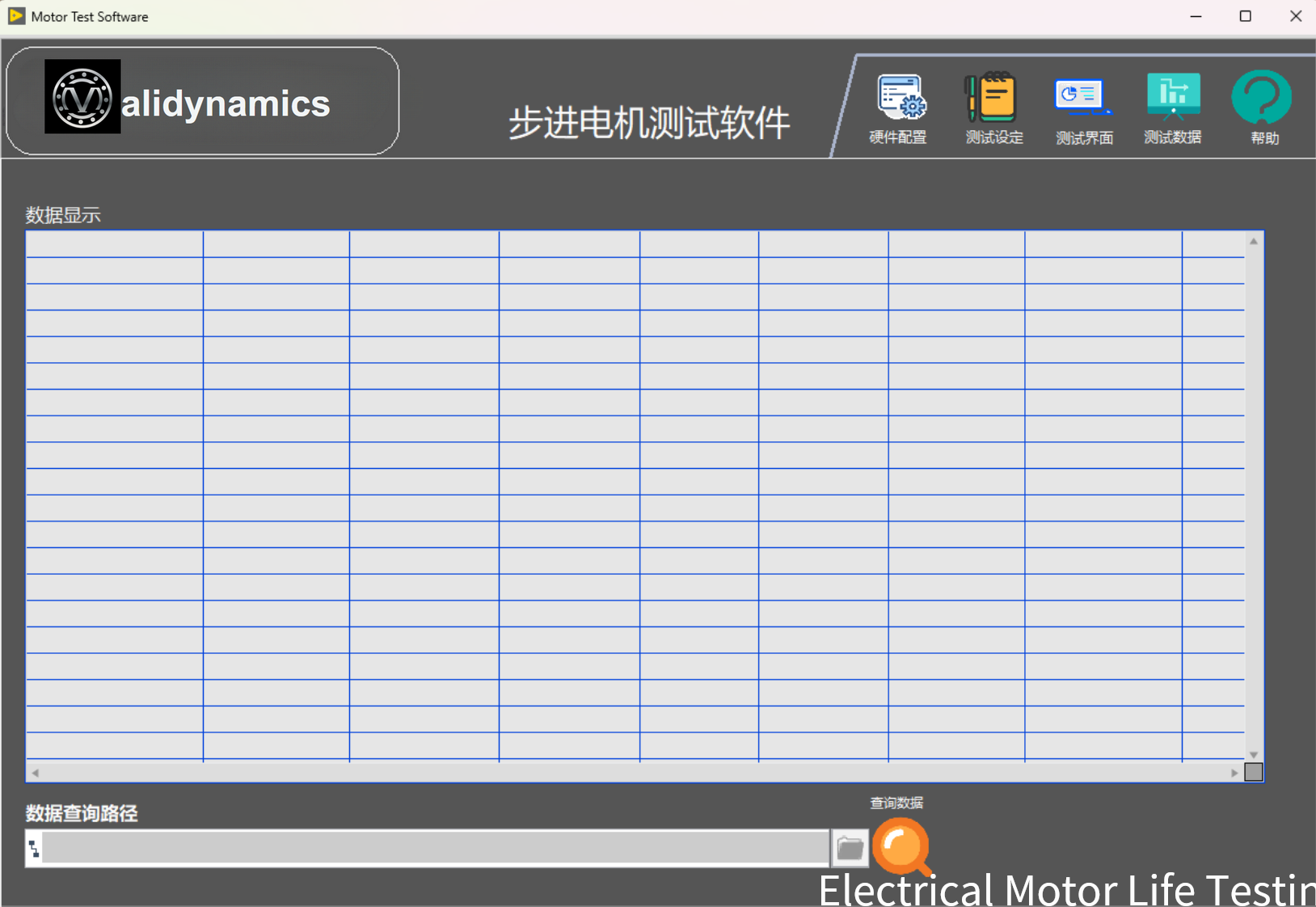

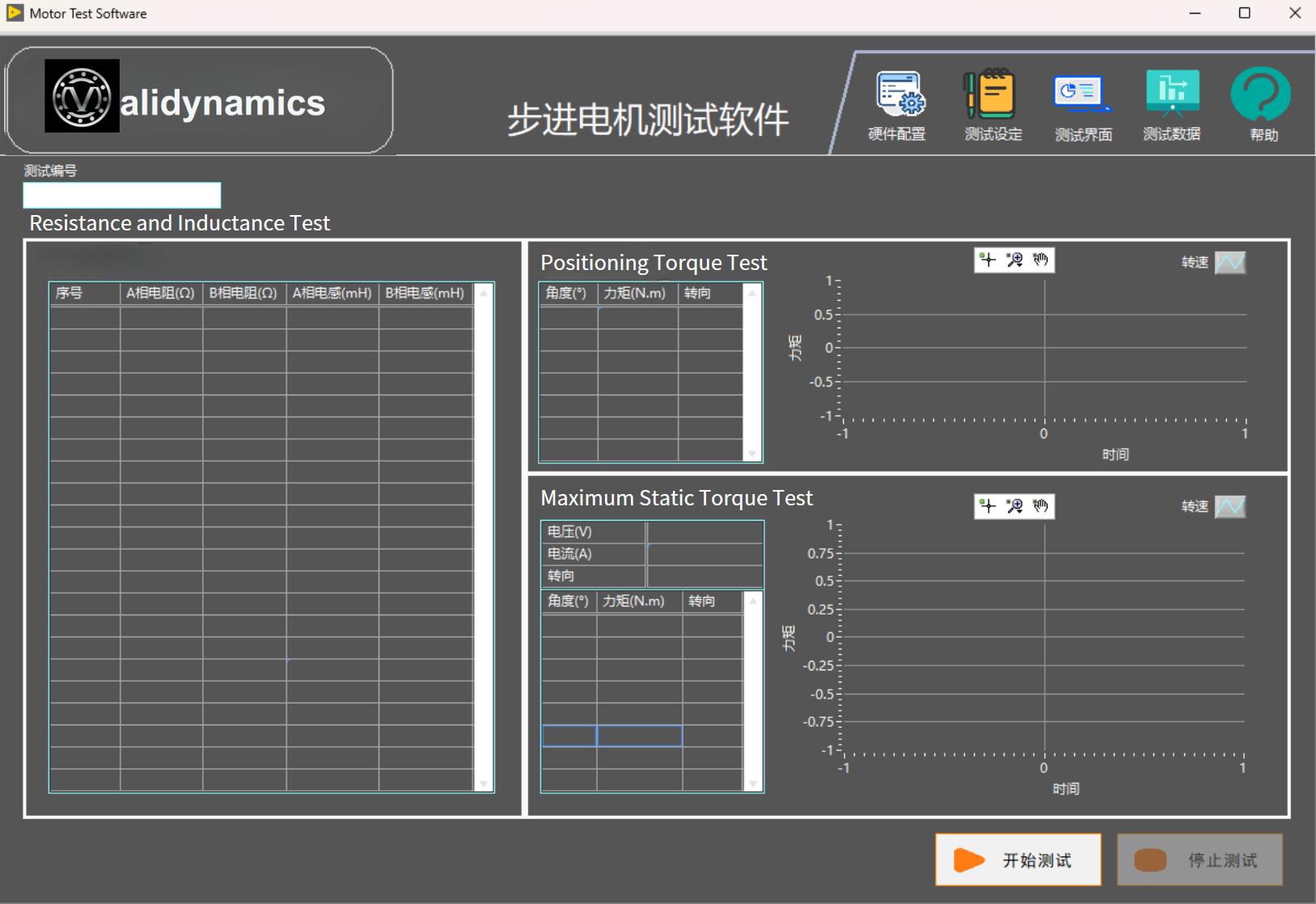

The system is customized to meet customer needs and primarily automates the testing and recording of:

This customized testing system is essential to efficiently meet the testing requirements for stepper motors.

Test Parameters:

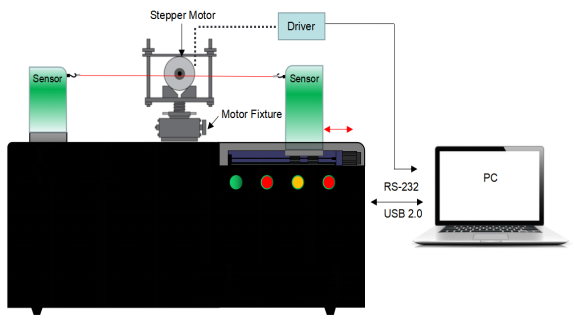

The stepper motor pull-in/pull-out torque testing device consists of the following components:

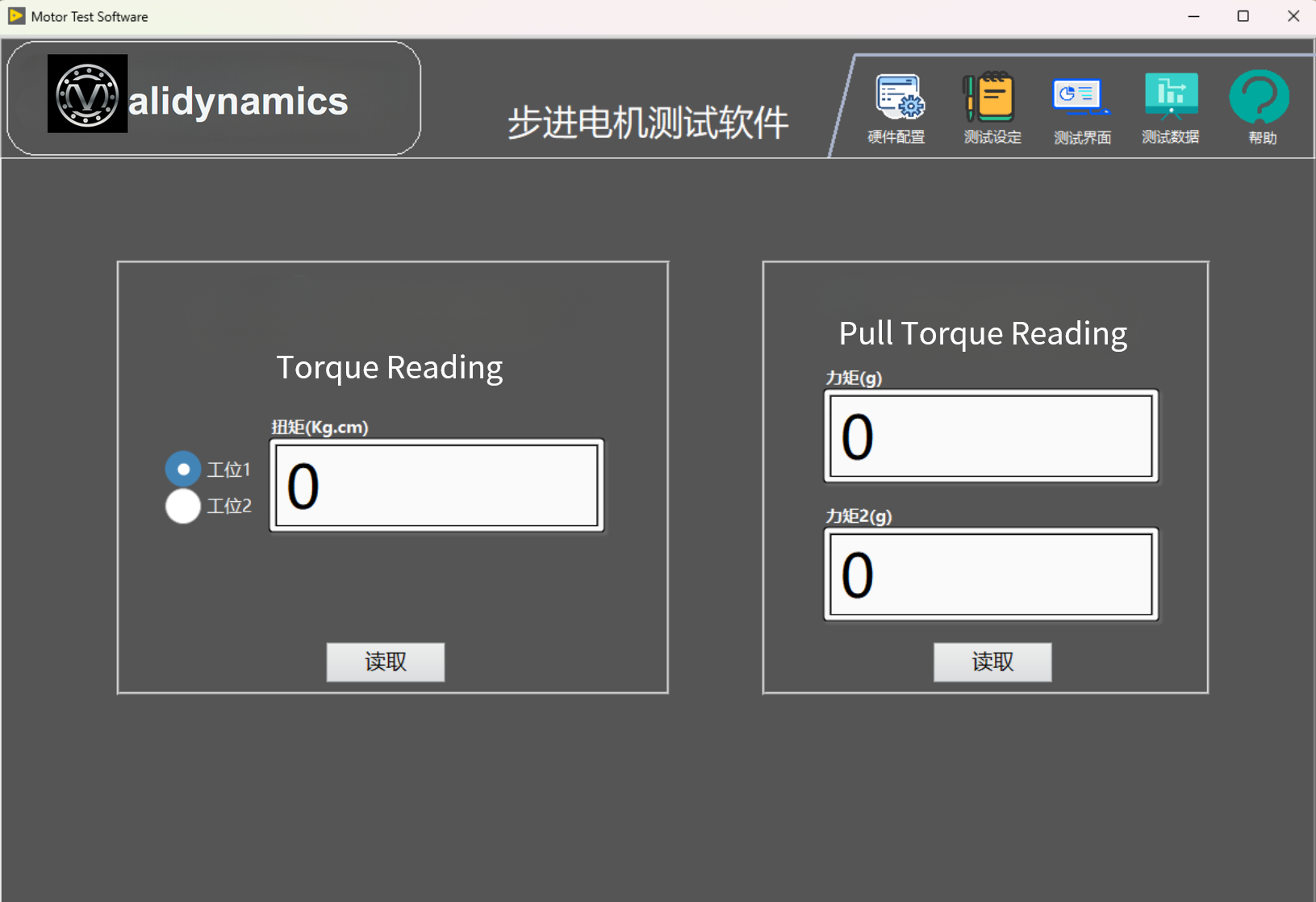

When testing, the stepper motor to be tested is securely fixed in place. A pulley (equipped with a planar magnet) is locked onto the motor’s output shaft, and the tensionless traction rope is wound around the pulley connected to the motor shaft. Both ends of the rope are hooked onto two force sensors.

The software controls the tested motor to rotate while simultaneously controlling the movement of the sensors via a single-axis robot. Torque is applied to the motor through the pulley. The software records the real-time values from the two force sensors and the rotational speed of the magnetic encoder until the motor loses step synchronization. The torque is then calculated using a formula, with the maximum torque at that frequency segment being taken as the pull-out torque.

Using this approach, the system measures the pull-out torque across different frequencies (rotational speeds) and generates a curve illustrating the results.

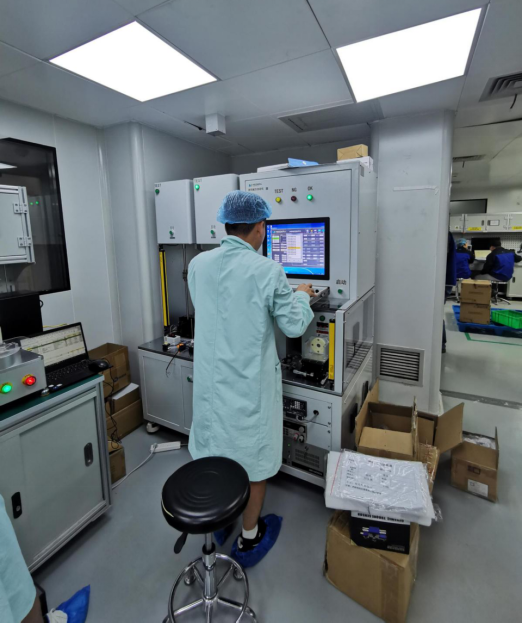

Application of Stepper Motor Pull-In and Pull-Out Torque Measurement System.