From our humble beginnings with a small hysteresis brake, we have grown to make it the core of our flagship products.

Equipment Overview

The motor lifetime testing equipment utilizes a braking system combined with an intelligent constant current source/servo motor + servo driver to form the testing system. The Motor Lifetime Testing System (ATC-1005) is an advanced solution that enables data collection through motor lifetime testing software, which operates under Windows 7/XP/10 operating systems.

Here’s the summarized description of the Motor Lifetime Test System (ATC-1005) and its components, with a focus on the working principle and software interface:

Motor Lifetime Test System (ATC-1005) Overview

System Block Diagram

The system can be divided into three major parts:

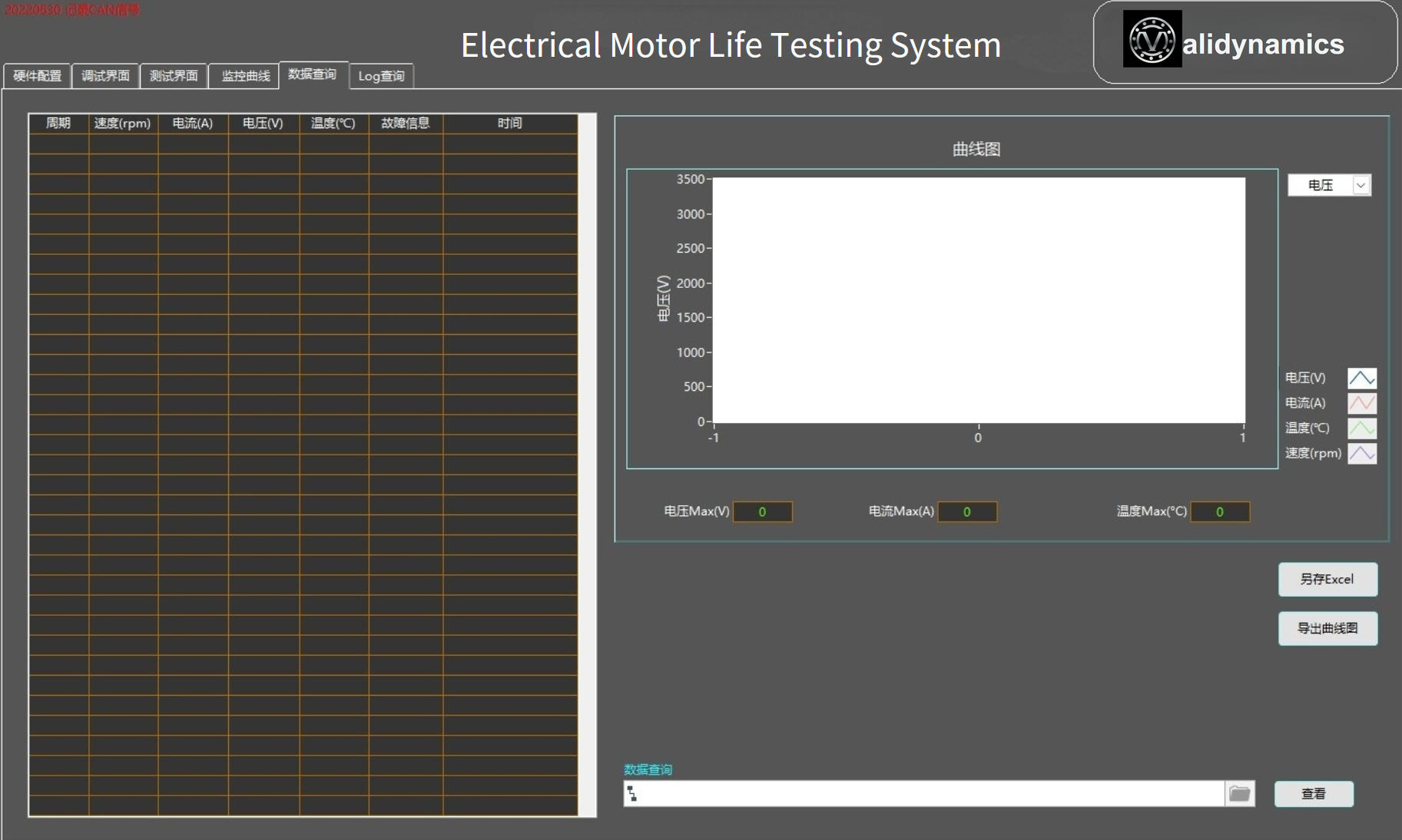

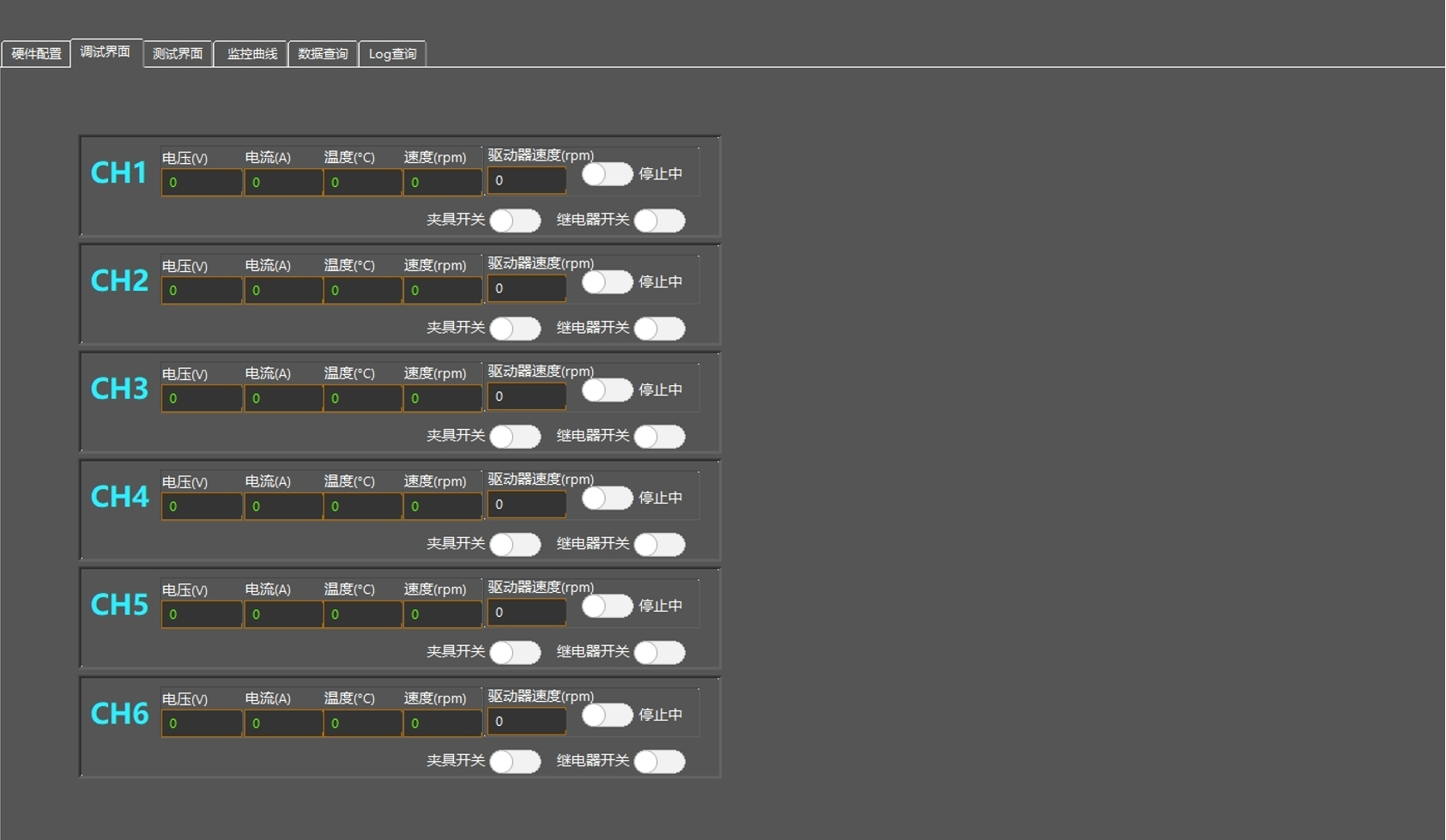

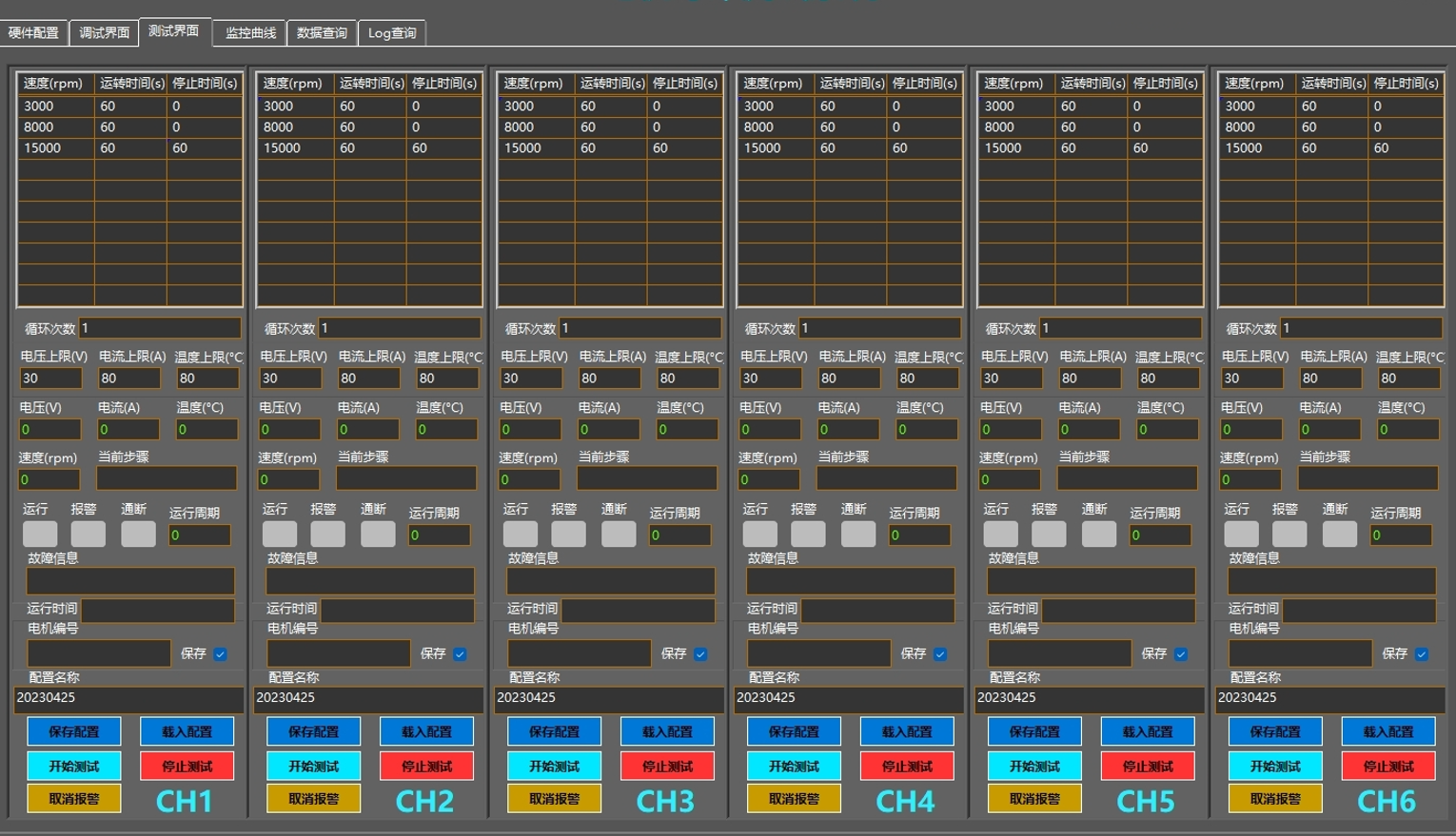

Data Acquisition Interface

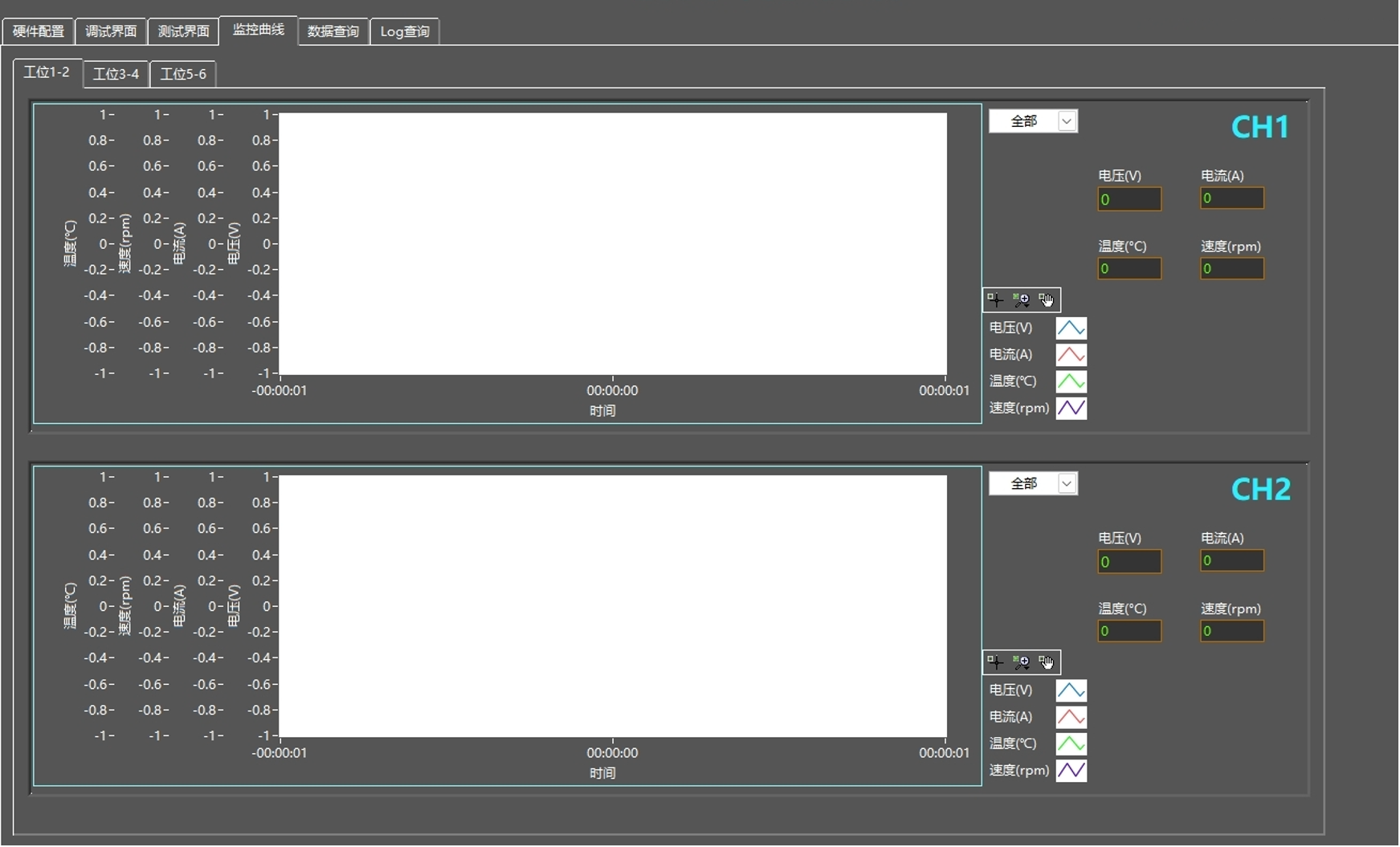

Real Time Curve Monitor

Software Interface

This motor lifetime test system helps simulate real-world conditions for motors, allowing for accurate testing and analysis of their performance over time. It is suitable for various applications and industries requiring motor longevity testing, such as automotive, robotics, and other sectors.

Software Interface

Software Interface

Motor testing systems for automation, robot, drone, aviation and medical equipment